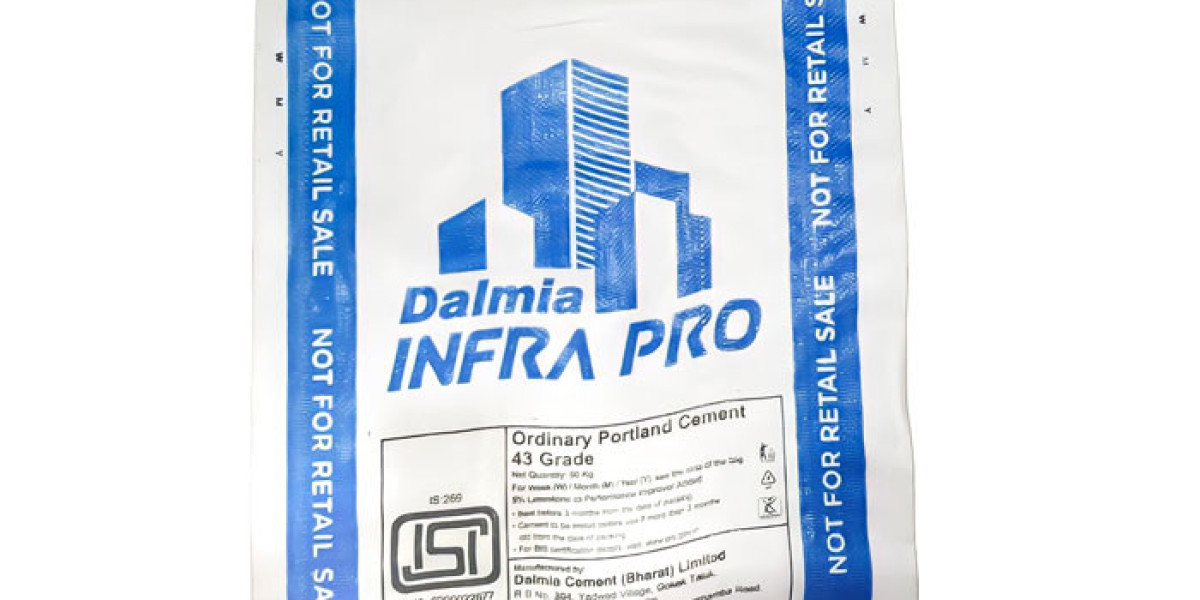

In the cement and construction industry, packaging plays a vital role in ensuring safe storage, easy handling, and efficient transportation of products. Among the most trusted solutions is the Valve Type Cement Bag, designed specifically to meet the demands of bulk cement packaging.

What are Valve Type Cement Bags?

Valve Type Cement Bags are made from woven polypropylene or paper materials and feature a valve at the corner of the bag. This valve allows cement or other powdered materials to be filled quickly and efficiently, without the need for stitching or sealing after filling. Once filled, the valve automatically closes, preventing leakage.

Key Features of Valve Type Cement Bags

Leak-Proof Design – Prevents cement spillage and wastage.

Easy Filling Process – The valve system enables faster and automated filling.

Durability & Strength – Strong woven fabric resists tearing and rough handling.

Moisture Resistance – Keeps cement dry and safe during storage and transport.

Customizable Options – Can be printed with branding and product details.

Applications

These bags are mainly used for cement packaging, but they are also suitable for other powdered or granular materials such as chemicals, minerals, and construction mixes.

Conclusion

Valve Type Cement Bags provide a safe, efficient, and economical packaging solution for industries that handle bulk powdered products. Their leak-proof design, ease of use, and durability make them the preferred choice in cement and construction sectors worldwide.